The lace making process

Making lace can be divided in 5 different steps, each requiring an exceptional level of precision, craftsmanship and dexerity : creating, preparing, making, subliming and final touches. Click to see the video

The steps of creating lace

Envisioning, Imagine, Creating

-

Since 1902

1.Sketching

It all starts with a sketch, preparing the entire lace making process.

Matching the current trends in fashion and style, the sketch brings the ideas to paper.

-

2.Designing

The sketch is handed off to the drawer who is going to establish the role and placing of every single thread. The designers take this shred of an idea and translate it into an actual - ready for manufacturing - working design, where each color and thread has been carefully placed and designed. Once the design is handed off, there is no changing the final product, this step is therefore crucial.

-

3.Perforation

This map of every thread is then digitalized then transferred on to cartboard cards designed to drive the bars which moved the threads into the machine thanks to the jacquard system. This is the card perforation process.

The steps of preparing the fabric

Expand, Roll, Assembling

-

steps of preparing

1.The Wapping, Weaving

Weaving lace requires preparation. Those steps are called weaving and wapping.

It consists in carefully and methodically spread threads on to rolls. The weaver will then create chains, and the wappers will then make rolls of gimps and floaching. Once being carefully examined, the chains and rolls can then be placed inside the leaver machine, where they will become intertwined and weaved together.

-

2.Wheeling

This is the heart of the machine, the part that makes the leavers machines so unique in the quality they deliver. The bobbin is a circular 0,70 mm wide metal piece that has to be filled with 150 meters of thread. The wheeler has to carefully roll the thread in the bobbins, creating the structure of the lace.

-

3.Pressers

Each bobbin is then handed off to the presser, who identifies, examines and sorts them according to their width, making them more harmonious, pressing some bobbins more than others in order to have a homogeneous result. The process finishes by putting them into an oven to stabilise the thread and thickness of the bobbins.

-

4.Mounting

This is another incredibly precise and complex step, in which each bobbin is placed in its cart, while also replacing the metal spring that provides the rotation speed needed to create the lace. Once the cart is filled, it is ready to be placed in the leavers and then weave the lace. It is ready to be placed in the leavers machine, and then start the weaving.

The steps of making the lace

Looking over, Observing, Calibrate

-

steps of making

1.Tulle making

With an expert eye, the tulle maker ensures that each specific thread is perfectly located accordingly to the design.

The tulle maker is able to tell from miles and miles of thread, which one is broken or not perfect. This expertise is unique and takes years of experience to master.

The final steps of making lace

Inspect, fix

-

final steps

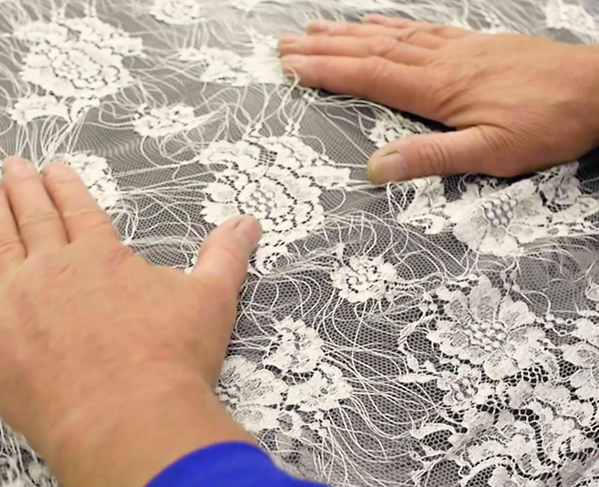

1.Inspecting

The inspectors are looking at any possible tiny inperfection in the lace ( holes, scratches ), marking them with chalk so that they will be mended. This is an indispensable step to ensure a product of premium quality and perfect finesse.

-

2.Patching up

The menders rewrite flowers and plain weave. Patiently, they follow the design, make defects disappear, redesign a border, fill in a gimp and, like a dream, reconstruct the slightest bit of background, whether honeycomb or cabling.

-

3.The Scalers

Then it is time to separate the piece from the others, by precisely cutting the edges of the lace, making each piece unique.

-

4.Folders

Folders then take over the pieces of lace to finalize the making process. They are the last to control the end result. A last cut, a last measurement, then they clip the lace, making it ready to be shipped around the world !